PET Fully Electric Stretch Blow Molding Machine Series for Cosmetics Bottles

Categories : Electric Blow Molding Machines

PET Fully Electric Stretch Blow Molding Machine Series for Cosmetics Bottles

Blow Molding Machine Multi Layer Series

Categories : Electric Blow Molding Machines

VS series: suitable for visistripe bottles (ex. Motor oil bottle) -TC series: for the production of two-color plastic containers or toys -TL series: suitable for 2-layer bottles (ex. Cosmetic bottle only outside layer with pearl or color & made of virgin material) -Double-head or 3-layer machine can be delivered to order

Blow Molding Machine PBSS SERIES 605 / 705 (S / D / T / Q)

Categories : Injection Blow Molding Machines

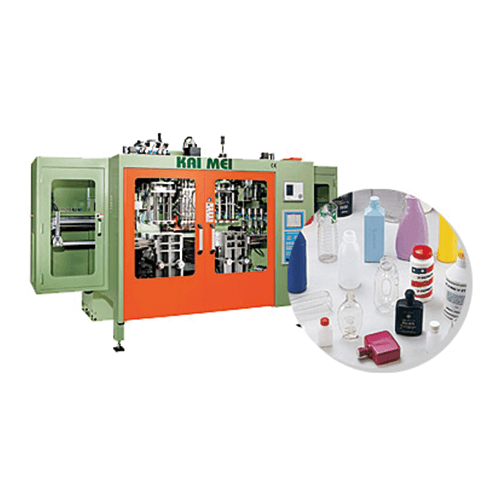

Double Stations Series Double station machine, full automatically, suitable for producing high-production runs of medium size bottles, ex. Cosmetic bottles detergents, etc. Mold-platen moves properly with high stability and high efficiency Three tie-bar horizontal traveling mold carriage combined with German linear motion guides for outstanding performance and high efficiency. This series is designed to meet high production and small size container requirements. Available to equip with auto de-flashing device and take out robot to achieve fully automatic and highly efficient production. 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, convenient and user-friendly operation.

Fully Electric Co-Extrusion Blow Molding Machine (Dual Diehead & Double Station / Visi Strip)

Categories : Automatic Blow Molding Machines

Chia Ming has developed Fully Electric Blow Molding Machine for the packaging industry producing pharmaceutical, cosmetic and beverage bottles in clean-room. Fully Electric Blow Molding Machine is a total new innovative design with servo motors controls which significantly reduce energy consumption, give higher production rate, noise level much reduced, in long term total production cost being dramatically reduced.

Automatic CO-Extrusion Blow Molding machine- P Series

Categories : Horizontal Blow Molding Machines

CO-EXTRUSION BLOW MOLDING MACHINE FOR MULTI-LAYER BOTTLES – Applicable for single and double station with single to multiple die heads for producing up to SIX-LAYER CONTAINERS (2 TO 6-LAYER CO-EXTRUSION), such as chemical bottles, catchup bottles, or cosmetic bottles. Co-extrusion application allows unrelated materials with different characteristics to be combined in one parison through Full Shine special-designed die head. This combination binds different materials, such as combining high-gloss outside layer and barrier layer by an adhesive layer between them in order to achieve the perfect outcome. Co-extrusion application is the advanced technology by the leading brand: Full Shine.

Small Blow Molding Machine

Categories : Electric Blow Molding Machines

Small-Continuous Type Blow Molding Machine This series model can produce small size containers ranging from 20mL to 10L for applications such as cosmetics, beverages, edible oil, pharmaceutical use, chemicals, housewares, and other industrial purposes. With the energy-saving system option, this machine can save up to 20% of power consumption. Some of the most common applications for small blow molding machines are: Lubricant oil bottles Laundry detergent bottles Cosmetic bottles Pesticide bottles Pharmaceutical bottles Multi-color kettles PVC cans Moreover, small blow molding machines can be customized according to the client’s needs of production: It can be a single or double station machine A visible stripe extruder unit can be added to observe liquid level It can include an auto-deflashing unit and many other features to make the machine as automatized as possible. An automatic extrusion blow molding machine is many times preferred because it leads to the reduction of manpower need which results in reduced costs, increased efficiency, and time savings for an organization.

Cosmetic Bottle / Detergent Bottle

Categories : Horizontal Blow Molding Machines

Good toughness Light weight Acid and alkali resistant Fast production Good transparency plastic bottle Good impact resistance Food grade container Precise preform neck Stable external appearance Easy processing Anti-aging